Metal Trims

trims - Metal roof

standing seam

Drip Edge

Valley

Ridge Cap

Hip cap

head wall

Head Wall

with kick

stucco

flashing

counter

flashing

wall

flashing

z bar &

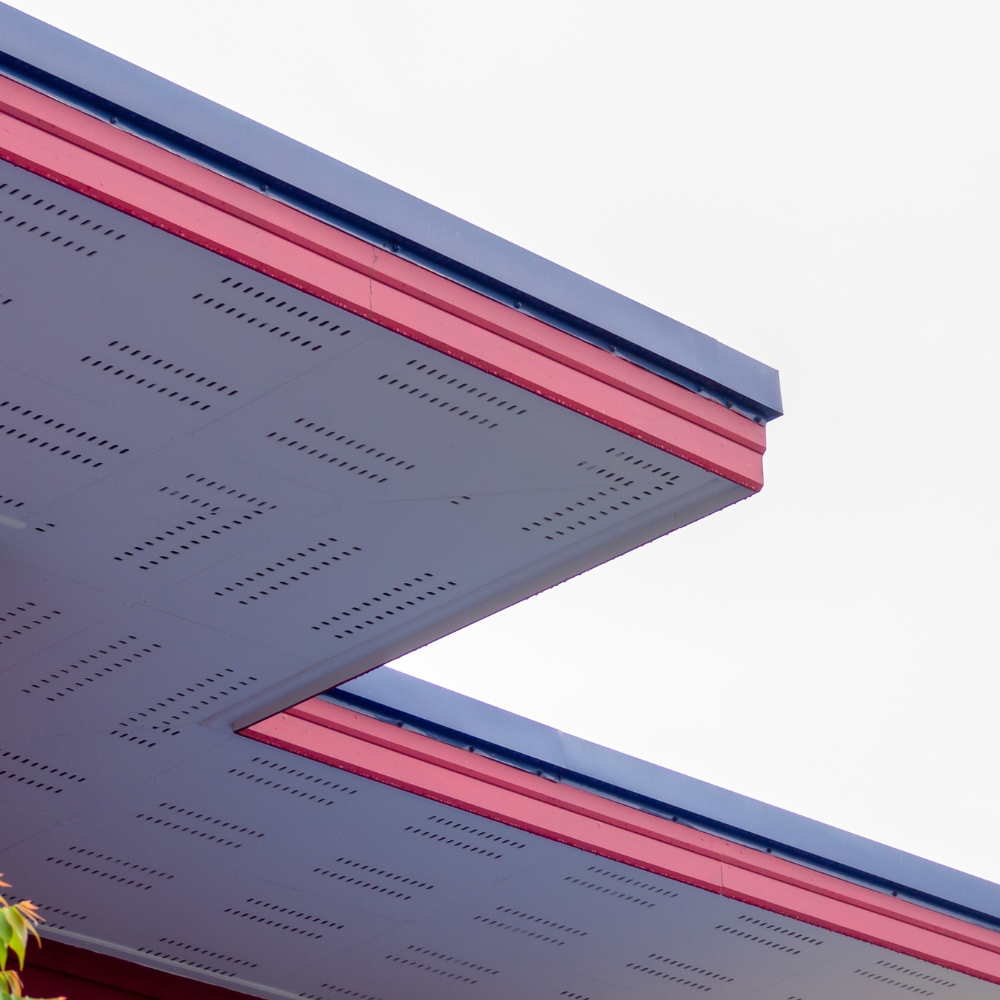

perforated

Use it along joints or seam points where two objects intersect, such as a vent pipe protruding from a roof. It can also be attached to brick walls or brick chimneys to force water downwards to a roof, gutter, or other surface below.

Use it around roof features (vents, chimneys, and skylights) to direct water away from wherever the metal panel meets a vertical surface like a wall or dormer.

Use it on a vertical wall along the gable side of the metal roof to keep the water that's dripping down a wall from getting underneath the metal roofing panels.

Use it at the lowest point of a valley, where two intersecting roof slopes meet, to prevent water from moving up the opposite slope and getting under the roof.

Use it at the peak or ridge where the two roof slopes meet to create a watertight connection between the two panels at the top of the roof.

Use it along the edge of the lower side of the metal panel to direct water away from the fascia and into the gutters.

Use it to hook onto a J or Z channel and extend it behind the exterior of a wall at the junction of a sloped metal panel and a wall.

Use it to transition the high side of a roof panel where it meets a headwall, chimneys, skylights, and other penetrations.

Use it at the point where two rising roof surfaces meet, such as a hip; to cover both the hip and ridge of the roof, where two adjoining slopes meet at the top.

r-panel

Ridge Cap

eave trim

eave

molding

fascia

rake and

corner

j trim 1

j trim 2

Inside angle

rake trim

universal

endwall

universal

sidewall

Use it at the peak or ridge where the two roof slopes meet to create a watertight connection between the two panels at the top of the roof.

Use it to cover the low side of a building following the roof's pitch when a gutter is not required to keep water away from the wall.

Use it to finish the look and prevent water penetration when two metal panels meet at an inside wall corner

Use it as a flashing to connect metal roof panels to vertical walls to prevent water from dripping down the wall and leaking into the roof.

Use it to finish the edges of a metal roof line where the roof panel edge meets the endwall panels.

Use it as a trim to connect the high side of metal roof panels to a vertical wall, such as a front or dormer.

Use it on the outside corners of building wall panels and on the roof edge rake where roof panels meet.

Use it as a closure and trim along the top edge of a sidewall and around doors and windows.

applications

standing seam

drip edge

standing seam

valley

standing seam

head wall

r-panel

rake & corner

r-panel

rake trim

r-panel

Inside angle

Our Metal Sheet Trim Collection

Standing Seam Trim Manufacturers

Sleek, interlocking panels ensure waterproofing and a modern finish.

Drip Edge

It directs rainwater away from fascia to prevent wood damage.

Valley

Channels roof runoff downward between intersecting slopes for efficient drainage.

Ridge Cap

Seals roof peak to prevent water infiltration and wind uplift.

Hip Cap

Covers roof hip intersections, adding strength and aesthetic appeal.

Head Wall

Connects sloped roof to vertical wall with watertight coverage.

Head Wall with Kick

Extended version redirects water outward, enhancing drainage and protection.

Stucco Flashing

Bridges stucco and roof edges to prevent water intrusion.

Counter Flashing

Overlaps base flashing to shield against moisture at intersections.

Wall Flashing

Protects vertical wall joints where water may enter beneath panels.

Z Bar & Perforated

Z bar seals wall edges; perforated trim improves ventilation efficiency.

R-Panel

Sturdy profile ideal for commercial roofs and exterior walls.

Ridge Cap

Covers roof peak to block water and reinforce structural integrity.

Eave Trim

Finishes roof edge while guiding runoff away from walls.

Eave

Lower roof edge where water drains, protected by trim manufacturers components.

Rake and Corner

Finishes sloped roof edges and exterior building corners securely.

J Trim 1

Cleans and seals vertical panel edges at windows and doors.

J Trim 2

Alternate size or style for tailored aesthetic and performance needs.

Inside Angle

Seals internal wall corners where two panels intersect neatly.

Rake Trim

Protects sloped roof edges and offers a finished appearance.

Universal Endwall

Connect high roof end to vertical walls with watertight closure.

Universal Sidewall

Joins vertical walls and roof sides to block water intrusion.

Applications of Metal Roof Trim Manufacturer

Drip Edge

Installed at the roof edge, rainwater into gutters, preventing rot, staining, and foundation issues efficiently.

Valley

Valley trims manage water runoff between two slopes, reducing pooling risks and protecting roof underlayment in metal roof valleys.

Head Wall

Used where the roof meets a vertical wall, this trim prevents wind-driven rain from entering the structure behind the panels.

Rake & Corner

These trims are used at roof rakes and building corners to prevent leaks while enhancing finish and edge protection.

Rake Trim

Rake trims prevent moisture penetration along panel edges while delivering a neat, defined finish to gable rooflines.

Inside Angle

This trim secures the internal corners of panel intersections, protecting against moisture while creating a clean, finished appearance.

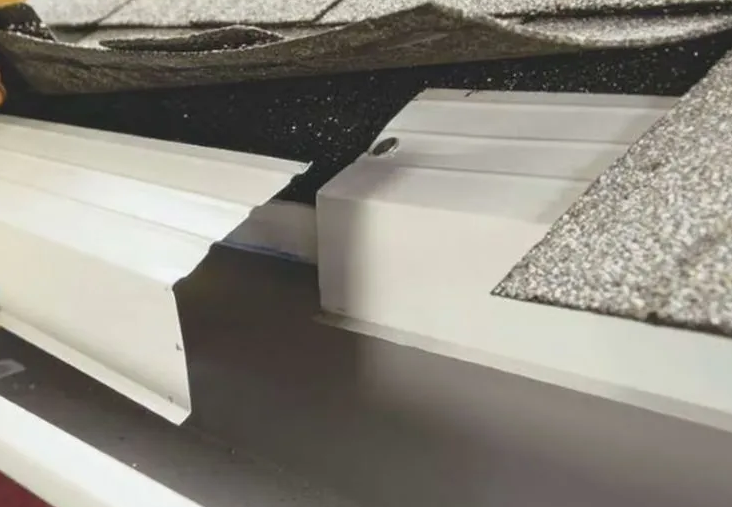

Shingle Drip Edge for Long-Lasting Metal Roof Flashing in San Antonio, Texas.

Provides a clean edge finish and prevents water intrusion on shingle roofs.

Application

Installed along eaves and rakes, it directs rainwater away from fascia, preventing rot, staining, and protecting roof decking underneath.

Why Contractors Choose Us for Steel Roof Flashing

24-Hour Turnaround

Receive custom or standard trim orders within 24 hours for maximum project efficiency and minimal downtime.

On-Site Tech Support

Our experts provide support directly on your site within four hours to guide proper trim installation and performance.

On-Site Manufacturing

With 100% in-house production, we maintain full quality control, accuracy, and speed across every stage of manufacturing.

Top-Ranked Service

Our 5-star ratings reflect our dedication to consistent quality, responsive service, and trusted expertise in the roofing industry.

Common Applications of Metal Trim in San Antonio

- Residential Metal Roofs: Standing seam, R-panels, and decorative trims

- Commercial Buildings: Rake, eave, and wall metal flashing for energy efficiency and code compliance

- Agricultural Facilities: Ridge and valley caps for barns and storage sheds

- Custom Structures: From pergolas to shipping container homes, our trims add polish and protection

shingle drip edge

Drip Edge

Application

shingle roof

drip edge

Customer reviews

Frequently Asked Questions

What types of metal trims do you manufacture?

We manufacture a complete range of metal trims on-site, including drip edges, ridge caps, rake trims, wall flashing, counter flashing, hip caps, headwalls, Z bars, and custom-fabricated designs.

Can I order metal trims specific to San Antonio building codes?

Yes, we tailor all metal trim in San Antonio to meet city codes and handle the region’s heat, rainstorms, and building inspection requirements, ensuring full compliance and superior durability.

Are your trims compatible with both standing seam and R-panel roofing systems?

Absolutely. We design and produce metal roof flashing, closures, and accessories that integrate seamlessly with both standing seam and R-panel systems, ensuring a perfect fit and watertight finish.

What material options are available for metal sheet trim?

We offer metal sheet trim in galvalume and painted options. These materials provide long-lasting resistance against corrosion, UV exposure, and moisture while enhancing architectural aesthetics.

Do you offer perforated trims for ventilation purposes?

Yes, we manufacture Z bar and soffit trims with perforation to promote ventilation in roof assemblies. These trims reduce heat buildup and help manage condensation in enclosed spaces.

Can I place small-batch orders for a custom project?

Yes, we specialize in small-batch trim production for custom projects. Orders can often be completed within 24 hours, giving contractors flexibility for repairs or precision-built architectural needs.

Do you deliver or offer pickup options for contractors?

Yes, we offer both delivery and pickup. Local contractors in San Antonio can schedule pickups or request fast delivery based on project urgency, location, and preferred delivery method.

What’s the difference between counter flashing and wall flashing?

Counter flashing is installed over base flashing to redirect water away from joints. Wall flashing protects the vertical connection between the metal panel and adjoining wall surfaces from moisture.

How do I know which metal trim is right for my structure?

Our expert team offers consultations and on-site tech support to assess your structure’s needs, recommend the right trims, and ensure proper water drainage, finish, and code compliance.